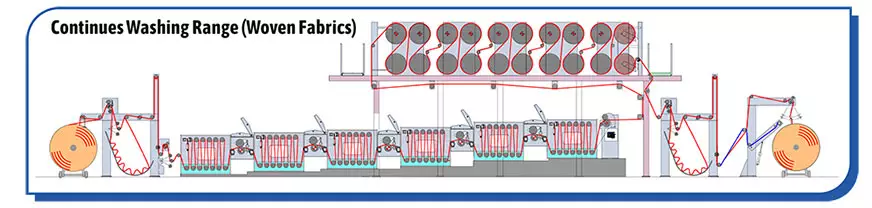

Washing Range (Woven Fabrics):

The finishing of textiles is obtained by means of chemical and mechanical process. The process contains always the impregnation, reaction and the subsequent washing. This is especially the case for finishing processes like bleaching, mercerizing and the washing off after the dyeing & printing. Thus the washing process is of significant importance within the chain of textile finishing. The final result in washing is depending on 4 major parameters. Chemistry, temperature, time & mechanic in use.

The chemistry, with the correct selection of the product in relation to the level of pollution , type of fabric and application. Temperature is an important cleaning factor where washing process are carried out. The mechanics, without which no efficient cleaning can take place, must be taken into account in the design. Washing process respectively the separation of solid and chemical impurities is a time related process.

“SSKI” washing compartment consists of a stainless steel trough with low liquor contents, partition can be provided to obtain effective counter current flow of water. The washed fabric comes in contact with fresh water which improves washing efficiency. There is high liquor turbulence with quick liquor exchange resulting in effective removal of dissolved chemicals and impurities.

- Top guide rollers 177dia are fixed in bearings with seal.

- Bottom guide rollers 177dia.are fixed in Carbon-Teflon self-lubricated bearing

- Compartment is equipped with direct-indirect heating arrangement.

- Dancer roll assembly for control the tension of fabric.

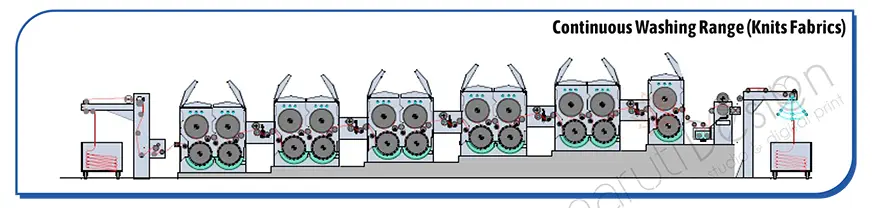

Washing Range (Knits Fabrics):

Excellent washing effect is due to the leading drum technology. The washing liquor penetrates the fabrics and forms a liquor flow on the front and back. With this method, dirt on the both side of fabric is quickly transported away. The washing effect is increased by 35-40% in perforated drum design with direct pressurized hot water jet spray breaks the hardness of closely knits fabrics. The hot water jet spray on top side of the fabric on the roller ensure optimum shrinkage which results in better feel, bulkiness, better finish and appearance of polyester viscose fabrics.