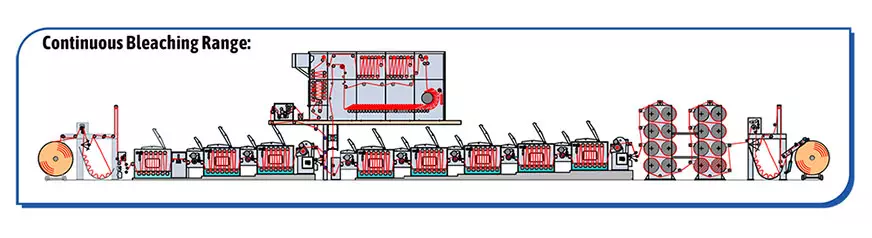

The bleaching of fabric gets it brightness that is evenly spread in the entire width of fabric. In this machine the fabric is treated with bleaching chemical and then it is steamed. This helps to increase the whiteness of the fabric so that it prepares for better dyeing.

Vacuum slot:

- Removal of substances before entering in to washing compartment. Our systems are designed to obtain a correct venture effect in order to extract the maximum level of humidity from the fabric.

- The vacuum slot is made with a unique high density polymer and is self-lubricated to ensure maximum humidity extractor without damage to the fabric structure.

- We are using high performance, low energy consumption and low maintenance vacuum pump.

Chemical Applicator:

- Housing with stainless steel construction. Maximum liquor application, No liquor exchange, Minimum liquor content & Uniform feed at both side of fabric over the width.

- Having Auto cleaning & Minimum temperature reduction of fabric.

- We can use in front of the bleaching steamer for bleaching liquor application & in front of dyeing steamer for application of dye liquors/chemicals.

Bleaching Steamer:

- Steaming is an important process in textile finishing like in dyeing plant & pretreatment. Steam allows fast energy transfer in to fiber.

- “SSKI” bleaching perform the bleaching process in optimum condition that guarantee a whiteness of fabric and high degree of absorbency.

- Housing construction from stainless steel material with segment construction. Inlet section with inclined / horizontal cloth guiding. Middle section with vertical cloth guiding . Driven perforated pulling roll and pendulum compensator for control the tension of fabric .

- Spray nozzles for cleaning & rapid cool down. Steam regulation by steam generation unit . Small distance between the guide rollers for prevention of crease.

- There are two sections, one is tight strand and other is roller bed. In tight strand section, the impregnated fabric with the liquor is heated up as per requirement and on roller bed section, we maintain sufficient dwell time for reaction purpose.