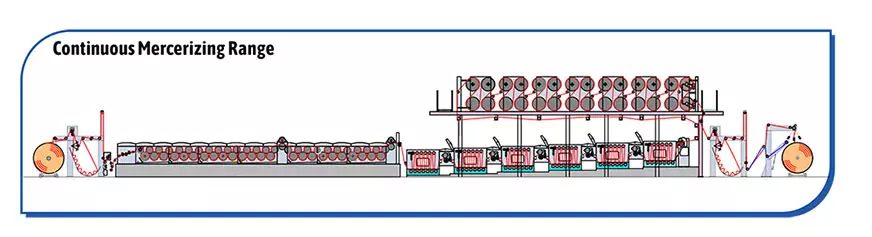

“SSKI” Mercerizing machine are designed to optimized the specific fabric quality & process requirement for cold/hot mercerizing for the dry on wet process.Mercerizing ensures that each yarn is activated to give the fabric a superior touch feel and luster in is outlook. This process adds value to the fabric and also prepares for a superior dyeing/printing result.

- Even fabric appearance.

- Maximum color brilliants

- Optimized dimensional stability.

- Increased tensile strength.

- Saving dye stuf

- Highest level of fabric luster.

Impregnating Section:

- Housing segments from stainless steel material.

- All bottom rolls are fixed and rotates on pedestal type sealed bearings

- Rotary drum filter with circulation pump & level management.

- Automation for caustic level.

- Indirect heating for caustic for hot mercerization.

- Caustic spray pipe between top two rubber rollers.

- Heavy two bowl mangle at the outlet.

- Very low width shrinkage.

Stabilizing Section:

- Housing segments from stainless steel material.

- All bottom rolls are fixed and rotates on pedestal type sealed bearings

- Counter flow washing with rotary drum filter and circulation pump.

- System for better recovery of caustic.

- Indirect heating for caustic for hot mercerization.

- Washed water spray pipes between top two rubber rollers.

- Heavy two bowl mangle at the outlet.

Lye Recuperator:

- Housing consists of a stainless steel material sub divided in to compartment.

- All top & bottom guide rollers in high execution.

- Perforated steam pipes are provided which allow steam to be blown in to the space between the cloth passage and providing a sufficient removal of caustic with steam.